Thank you for Subscribing to Food Business Review Weekly Brief

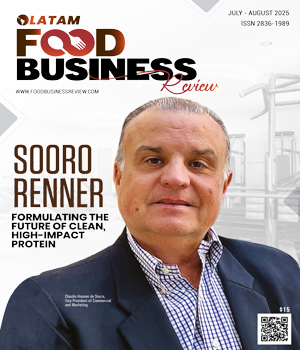

Few ingredients have gone from agricultural waste to global health staple quite like whey. Once discarded, it now powers the billion-dollar fitness and nutrition industry. Behind this transformation are innovators who didn’t just see a byproduct—they saw potential. One of them is Sooro Rennerr, a company reshaping the functional dairy landscape through innovation, scale, and service. “Our growth has always been guided by precision, trust, and deep technical partnerships— starting from Brazil and now reaching the world,” says Claudio Hausen de Souza, Vice President of Commercial and Marketing. Today, Sooro Renner is the largest whey processor in Latin America by volume, with more than two decades of experience. It supplies high-quality ingredients for both human and animal nutrition and holds full export licensing to serve clients worldwide across a wide array of food and beverage sectors. Its product portfolio is designed for both performance and versatility. The company’s Whey Protein Isolate 90 percent delivers ultra-high protein content with less than one percent milk fat—ideal for use in nutritional supplements and high-protein dairy products. For broader application needs, its Whey Protein Concentrate 80 percent is available in regular, instant, and lactose-free forms, making it suitable for everything from protein shakes to ice creams and baked goods. The company also offers WPC 60 percent and WPC 34 percent, which provide excellent texture, solubility, and performance in dairy beverages, energy drinks, and processed foods. Sooro Renner’s whey powder—a blend of lactose, protein, and reduced mineral salts—adds rich dairy flavor and enhances the consistency of chocolates, processed meats, and more. In addition, it produces permeate, which is used in both food and feed formulations, ensuring every element of whey is optimized.

Foodservice Equipment In Latin America 2025

The foodservice industry is undergoing a dynamic transformation, driven by cutting-edge equipment and technology, to elevate and redefine the dining experience. Middleby (NASDAQ: MIDD), a leading developer of advanced solutions for commercial, industrial and residential foodservice, is at the forefront of this transition, elevating commercial kitchens globally with its modern products and systems. It operates in three business segments, including commercial foodservice equipment, residential appliances and food processing solutions. Middleby’s wide range of high-quality, customized products under various categories, like cooking equipment and beverage solutions, are designed to meet the evolving customer needs. Some of its popular products include commercial griddles, charbroilers and fryers, which are designed to streamline food preparation while maintaining high-quality standards. “The company has developed innovative solutions that have been quickly accepted as the industry standard, allowing customers to automate production lines with a low cost of ownership,” says Timothy FitzGerald, CEO. Middleby constantly expands its product offerings and makes key acquisitions to strengthen its position. Products like heavy-duty frying systems, slicers and breading equipment give the company a competitive edge. Its wide range of brewing and dispensing equipment is perfectly equipped to cater to the growing demand for quality drinks. One of its flagship products, the commercial griddle, offers unmatched performance and a perfect cook with every use. These are designed to help restaurants maintain consistency and maximize efficiency, even during the busiest hours. Staying on top of future trends like automation, digital technologies and IoT is top of mind at Middleby. One of the most significant developments in its portfolio is integrating modern technology into commercial kitchens. Its open kitchen IoT system allows restaurant owners and operators to remotely monitor and manage commercial cooking equipment across multiple locations through an easy-to-use online dashboard. This gives real-time insights into equipment performance, alerts for maintenance needs and a clearer understanding of energy consumption, all of which contribute to running a more cost-efficient and productive kitchen. Its automated frying and pizza bots transform how food is prepared using advanced robotics technology to ensure consistent quality in each dish. These innovations streamline kitchen operations, reducing manual labor and allowing businesses to focus on essential aspects of operations while delivering high-quality food to customers.

Food Processing Solutions Provider

On a delightful Saturday morning, the facilities director of West Fargo Public Schools received an alert on his phone regarding a freezer malfunction at one of their campuses. It was a notification from TempLink’s monitoring system. Reading the message, the director realized there was a bulk order of ground beef, along with other inventory, stored in the freezer that had been shipped on the previous day for the school district. Upon checking, they found the freezer temperature was heating up due to an unknown failure and filled it with dry ice until the HVAC team arrived. The instant alarm activated by TempLink’s solution, composed of gateways, sensors, and a dashboard—saved all the food and inventory worth over $200,000. Sensors within the cooling unit detected the rise in temperature and communicated the issue to the dashboard via a gateway. Utilizing the reliability and scalability of Amazon Web Services (AWS) Cloud, the system promptly sent an alert from the dashboard to the director’s phone, ensuring they were immediately informed. TempLink integrates LoRaWAN technology into all its wireless sensors for better connectivity, eliminating common connectivity and range issues of Bluetooth and Wi-Fi-based systems. With its high-performance rating, LoRaWAN reduces power consumption, offers a longer range with less interference from other frequencies, and provides a more stable connection, scalability, and security. “Leveraging over three decades of combined experience, we have built high-sensitivity devices that offer superior connectivity, reliable monitoring, and a cost-effective solution for our customers,” says Gary Tharaldson II, CEO.

CXO INSIGHTS

Is The Food Industry Inclusive?

Angelo Kawakami, Innovation Manager, Panco

From Bean to Bar: The Chocolate Journey at Barry Callebaut

Igor Annibal, Head of Sales - Food Service, Barry Callebaut

The Challenges to Selling Fresh Berries Around the World

Victor Cedillo, Global Expansion Sales Director, Driscoll’s

The Experience of Serving the Customer's Customer - and How We Can Grow From It

Cristina Faganello, Managing Director Food South America, Cargill

The Evolution of Boali: A Tale of Pioneering the Healthy Food Restaurant Industry and Entrepreneurial Excellence

Victor Giansante, Director of International Development, Boali

Crafting Brand Excellence: Navigating the Commoditized Egg Market with Success

Andre Carvalho, Director of Marketing, Innovation and Business Unit Leader - Egg Products & Drinkable Eggs, Mantiqueira Brasil

Cultivating a Greener Future: Grupo Solave's Environmental Commitment

Axel Mederos Suarez, Environmental Sustainability Chief, Grupo Solave

Sustainable Livestock Farming: Technology and Innovation in Control of the Chain

Tamara Lopes, Corporate Executive Sustainability Manager, Minerva Foods

What Does Mexican Agriculture Need to Truly Exploit its Potential in International Markets?

Mauricio Ricaud, Founder & CEO, Rising Farms

IN FOCUS

A Strategic View of Latin America's Diverse Protein Industry

The Latin American protein industry is evolving in response to rising demand for animal proteins and plant-based alternatives, driven by consumer preferences, agricultural strengths, and technological innovations in production.

Food Processing Solutions Reshaping the Future of Sustainable Food in Latin America

Latin America is innovating sustainable protein sources through diverse solutions like indigenous crops, precision fermentation, cellular agriculture, and insect proteins, transforming its food landscape.

EDITORIAL

Latin America’s Next Chapter In Food Innovation

Latin America’s food sector is rewriting its story, with protein production at its core. Producers are turning to new technologies and scalable models to serve local and global markets as demand grows for sustainable, traceable, highquality protein. From plant-based innovation to modernized poultry and beef supply chains, the region is working to unlock its full agricultural potential.

Foodservice operators and equipment makers are moving forward with this shift. In a post-pandemic world where people want speed, quality and healthier options, the need for efficient and resilient foodservice has surged. Kitchens are adopting smarter, space-saving equipment. Cloud kitchens and quick-service restaurants are using automation to handle rising delivery volumes.

Processing plants are rethinking how they run, putting agility, sustainability and digitization at the center. Flexible batch manufacturing, energy-efficient cooling and eco-friendly packaging show how the industry is rebuilding its backbone for the future.

Market projections reflect this momentum. Latin America’s alternative protein market could reach $1,244 million by 2035, growing five percent annually. The food service equipment segment will hit $7,491 million by 2035, lifted by growth in Brazil, Mexico and Colombia. Food processing machinery alone could surpass $9,292 million by 2033, with steady growth year after year.

These shifts add to a food production and service ecosystem that is smarter, more resilient and better prepared to meet changing consumer and climate expectations.

The magazine features thought leadership articles from Igor Annibal, Head of Sales - Gourmet Brazil at Barry Callebaut Group, emphasizing that real progress lies in deep advisory, long-term partnerships and data-informed decision-making. Mauricio Ricaud, Founder & CEO, at Rising Farms, also offers a powerful reminder that food innovation begins with structure. He makes the case for scalable models, access to capital and professionalized talent as the bedrock of Latin America’s globally competitive protein and agtech sector.

This edition features Top Proteins Production in Latin America 2025, Foodservice Equipment and Food Processing Solutions Provider. We hope you find the right partner to meet your organization’s needs.