To achieve success, a food and beverage business must embrace safety and quality as its fundamental values. The persistent efforts by food processors and producers to provide fresh and healthy products stem from a deep-seated commitment to protecting customers and maintaining integrity. Organizations actively revamping their cleaning and sanitization mechanisms to mitigate known microbiological risks and prepare for emerging threats have turned their attention to ozone, a powerful and natural compound capable of replacing chemical disinfectants and many cleaning solutions.

To achieve success, a food and beverage business must embrace safety and quality as its fundamental values. The persistent efforts by food processors and producers to provide fresh and healthy products stem from a deep-seated commitment to protecting customers and maintaining integrity. Organizations actively revamping their cleaning and sanitization mechanisms to mitigate known microbiological risks and prepare for emerging threats have turned their attention to ozone, a powerful and natural compound capable of replacing chemical disinfectants and many cleaning solutions.

Advanced Ozone Integration (AOI) is a frontrunner in harnessing the potential of ozone to revolutionize food processing. EcoPrO3, the company’s robust, proprietary ozone technology platform, is designed and integrated specifically for the customer’s application to effectively clean and sanitize food and food-contact surfaces while improving facility and product safety.

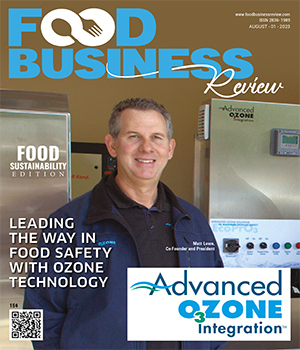

“The ozone alternative to chemical cleaning has been around for decades. But AOI has changed the game by working closely with customers to integrate the system for specific applications, provide them with the right controls and safety measures, and educate them so they stay compliant with regulatory and food safety standards,” says Matt Lowe, Co-Founder and President and CEO of Advanced Ozone Integration.

“The ozone alternative to chemical cleaning has been around for decades. But AOI has changed the game by working closely with customers to integrate the system for specific applications, provide them with the right controls and safety measures, and educate them so they stay compliant with regulatory and food safety standards,” says Matt Lowe, Co-Founder and President and CEO of Advanced Ozone Integration.

When Science Meets Engineering

By harnessing the power of the unstable O3 molecule, ozone effectively attacks harmful bacteria and viruses. This fascinating natural phenomenon, born from mother nature and captured and harnessed by Nikola Tesla over a century ago, has proven to be a formidable ally in combating microbial threats. This journey from nature’s spectacle to modern-day applications perfectly captures the crossover between science and nature, a testament to the human commitment to fostering a safer, cleaner, and more sustainable world.

Our Core Team has been Heavily Involved with Early Ozone Efficacy and Safety Validation Studies for Decades

Aqueous ozone, when sprayed on meat and poultry equipment, and wine and beer processing tanks and pipes, acts as a highly potent antimicrobial agent. This oxygenated water then flows down the sewers without any adverse effect on the pH of the wastewater while reducing biochemical oxygen demand loads, odor, and chemical discharges.

Aqueous ozone, when sprayed on meat and poultry equipment, and wine and beer processing tanks and pipes, acts as a highly potent antimicrobial agent. This oxygenated water then flows down the sewers without any adverse effect on the pH of the wastewater while reducing biochemical oxygen demand loads, odor, and chemical discharges.

AOI’s turnkey ozone systems are also engineered for line optimization, allowing food processors to gain maximum efficiency from their production lines. These efficiencies result in increased runtimes, on-demand sanitizing, and a systematic approach to allergen separation that can completely revolutionize food safety protocols. Unlike many conventional solutions, ozone maintains its efficacy over time.

Since ozone is generated onsite near its point of use, it also saves clients the expense and hassle of transporting and storing harmful chemicals. This also goes a long way in improving stakeholder safety, which is a major concern for food and beverage companies. “Our primary goals are to engineer ozone equipment to be automated, effective, and extremely simple to operate,” says Lowe. “That is then followed up with developing and integrating ozone applications to provide an alternative to common chemical consumption while improving product safety, personnel safety, and the environment.”

Since ozone is generated onsite near its point of use, it also saves clients the expense and hassle of transporting and storing harmful chemicals. This also goes a long way in improving stakeholder safety, which is a major concern for food and beverage companies. “Our primary goals are to engineer ozone equipment to be automated, effective, and extremely simple to operate,” says Lowe. “That is then followed up with developing and integrating ozone applications to provide an alternative to common chemical consumption while improving product safety, personnel safety, and the environment.”

Modern food processing is driven by data traceability and accountability, and AOI’s system is built on this premise. All data, whether system operation parameters or historical treatment records, is logged in the system in real-time and can also be accessible to customers remotely. They are also provided with daily reports on key system parameters, which facilitate better monitoring and diagnosis. These upgrades have been essential in the efficacy and regulatory approval of ozone.

A Path to Environmental and Financial Sustainability

The environmental and financial advantages of AOI’s ozone solution make it a compelling value proposition for the dynamic and forward-thinking food industry. The EcoPrO3 system has a low energy demand, and its cold-water application optimizes utility costs, contributing to significant savings. In addition, ozone naturally dissipates after use, leaving no residual contamination, which is an environmentally favorable characteristic that makes the technology a perfect fit for the industry’s growing emphasis on green practices.

-

The Ozone Alternative to Chemical Cleaning has been Around for Decades. But AOI has Changed the Game by Working Closely with Customers to Integrate the System for Specific Applications, Provide them with the Right Controls and Safety Measures, And Educate them so they Stay Compliant with Regulatory and Food Safety Standards

Reduced chemical usage, plastic waste, and the reduction of carbon footprint exposure are key benefits supporting the company’s mission to drive a sustainable future. AOI is steadfast in its commitment to positively contributing to an already threatened environment by replacing the harmful and carcinogenic chemicals currently used in the industry. “Our customers are now recognizing that traditional sanitation chemicals pose further challenges once down the drain,” says Dave Rye, Co-Founder and Vice President of AOI. “We can now play a much greater role in bringing forward meaningful sustainability performance.”

The company’s solutions have also earned the endorsement of the FDA, USDA, and EPA, which is a testament to its commitment to maintaining the highest standards of safety and efficacy in its offerings. Approvals from top regulatory bodies elevate AOI’s credibility in the market, and assure customers who are keen on maintaining the highest quality standards.

A Team Powered by Expertise and Dedication

At the heart of AOI’s trailblazing scientific approach lies its talented team of industry and engineering experts. Boasting a combined experience of 150 years in the ozone and food manufacturing sectors, the team stands out as its greatest asset. This collective experience enables them to identify potential applications and implement effective ozone solutions that seamlessly integrate into existing processes.

“Our core team has been heavily involved with early ozone efficacy and safety validation studies,” says Rye. “Our scientific and engineering teams weigh in on all of our customer solutions, leading to our successful implementations in the field.”

“Our core team has been heavily involved with early ozone efficacy and safety validation studies,” says Rye. “Our scientific and engineering teams weigh in on all of our customer solutions, leading to our successful implementations in the field.”

From initial ideation to final execution, AOI’s team is actively involved in every step, guaranteeing the superior performance and efficiency of their solutions. Their unrivaled expertise, passion for innovation, and dedication to providing the best ozone solutions demonstrate the company’s commitment to revolutionizing the food processing space. This ongoing contribution sets AOI apart from the competition, making it a true leader in the field.

Customer Success in the Poultry Processing Industry

The impact of AOI’s ozone solutions is best illustrated by its library of customer success stories. A key example includes a prominent poultry processing plant that integrated the ozone technology into their new facility, significantly improving their microbial control. Pathogens were effectively reduced, resulting in safer food products and an optimized production line.

“In poultry processing, there’s always a large focus on microorganisms and bacteria,” says Lowe. “However, in the facility where our system was leveraged, the client experienced the lowest microbial levels and overall safest equipment (line heath) than any other department.”

Beyond these heightened safety measures, the client also realized significant utility savings due to reduced water use and energy demand. Encouraged by these results, they now plan to integrate AOI’s ozone solution into many other facilities and locations. They also plan to expand use to include wastewater treatment, taking another step in their journey toward total environmental responsibility.

Beyond these heightened safety measures, the client also realized significant utility savings due to reduced water use and energy demand. Encouraged by these results, they now plan to integrate AOI’s ozone solution into many other facilities and locations. They also plan to expand use to include wastewater treatment, taking another step in their journey toward total environmental responsibility.

Setting the Stage for Future Innovations

The roadmap is clear—expansion and innovation. AOI plans to widen the applications of its unique technology, targeting the egg industry for its next phase of growth. It envisions a future where the entire food processing industry leans toward ozone technology as an environmentally responsible alternative to traditional chemical methods.

“We are always looking into additional applications for this scientific solution,” says Lowe. “Traditional chemicals have been accepted for so many years, so we hope to catalyze a shift for people to see that ozone is natural, organic, and effective.”

By seizing the power of ozone and unleashing its potential in industries that are ripe for change, AOI is creating a compelling roadmap for a future where food processing is safer, more efficient, and more respectful of our planet. Through its cutting-edge solutions, it is enabling industries to step into an era where food safety and environmental responsibility go hand-in-hand. With this robust value proposition and a clear vision, there’s no doubt AOI is a change-maker in the food processing industry.

Company : Advanced Ozone Integration (AOI)

Headquarters :

Atascadero, CA ManagementMatt Lowe, Co-Founder and President; Ray Brasser, Director, Technology Development; Joe Cannavino, Vice President of Engineering

Thank you for Subscribing to Food Business Review Weekly Brief